Product Specification Sheet: A B2B Guide to Manufacturing

- By Grace

- Updated on

You've found the perfect sample. It looks, feels, and performs exactly as you envisioned. You sign off on it, excited to move to mass production. But a critical question lingers: what guarantees that the 10,000th unit produced will be identical to the "golden sample" in your hand?

This gap between the sample and scaled production is where ambiguity can silently kill a product launch. At KLCOSY, we eliminate this risk by establishing a "Manufacturing Constitution" before the first unit is ever made: the Product Specification Sheet. This document is far more than a list of features; it is the single source of truth, a binding agreement that defines every critical aspect of your private label product.

In this guide, I'll break down how we create and manage this vital document. I'll show you how it becomes the unbreakable standard for quality, how we manage changes, and how it protects your investment from the risks of unauthorized component swaps and "quality fade."

What Makes a Spec Sheet More Than Just a List of Features?

You’ve seen spec sheets before—often simple documents with basic dimensions and features. But a truly effective spec sheet is a comprehensive technical blueprint that leaves zero room for interpretation.

A great spec sheet is a detailed, multi-page document that meticulously defines every aspect of the product, from the grade of plastic used to the decibel level of the motor. The lead engineer at a medical device company told me, "The KLCOSY manufacturing specifications were the cornerstone of our regulatory submission. Its level of detail gave us—and our auditors—complete confidence in the product's consistency and safety."

A world-class specification sheet is the output of a deep, collaborative engineering review. It translates your vision into a set of precise, measurable, and verifiable parameters that serve as the ultimate reference point for our engineers, your quality inspectors, and our entire supply chain. Its purpose is to replace assumptions with data, creating a shared, unambiguous understanding of the final product. By investing the time to define these details upfront, we prevent the costly disputes that can arise from vague expectations later on.

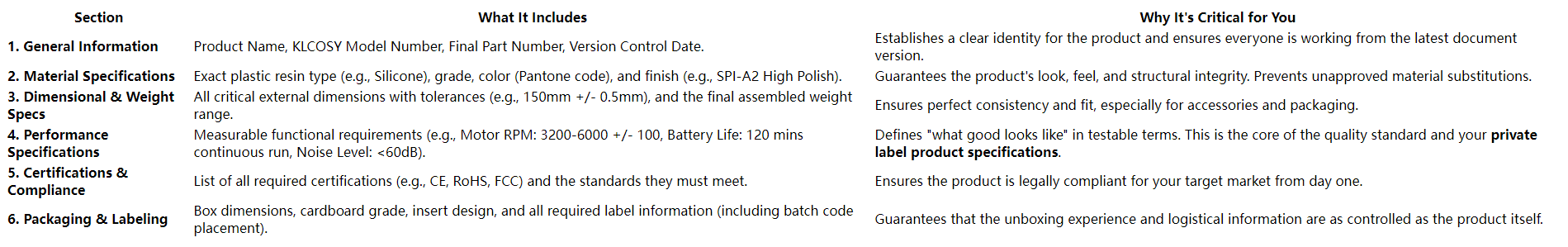

The Anatomy of a KLCOSY Specification Sheet

So, How Does This Document Become Our "Golden Standard"?

A document is only as powerful as the process that governs it. How does the spec sheet move from being a helpful guide to being the absolute, binding authority for every single unit we produce?

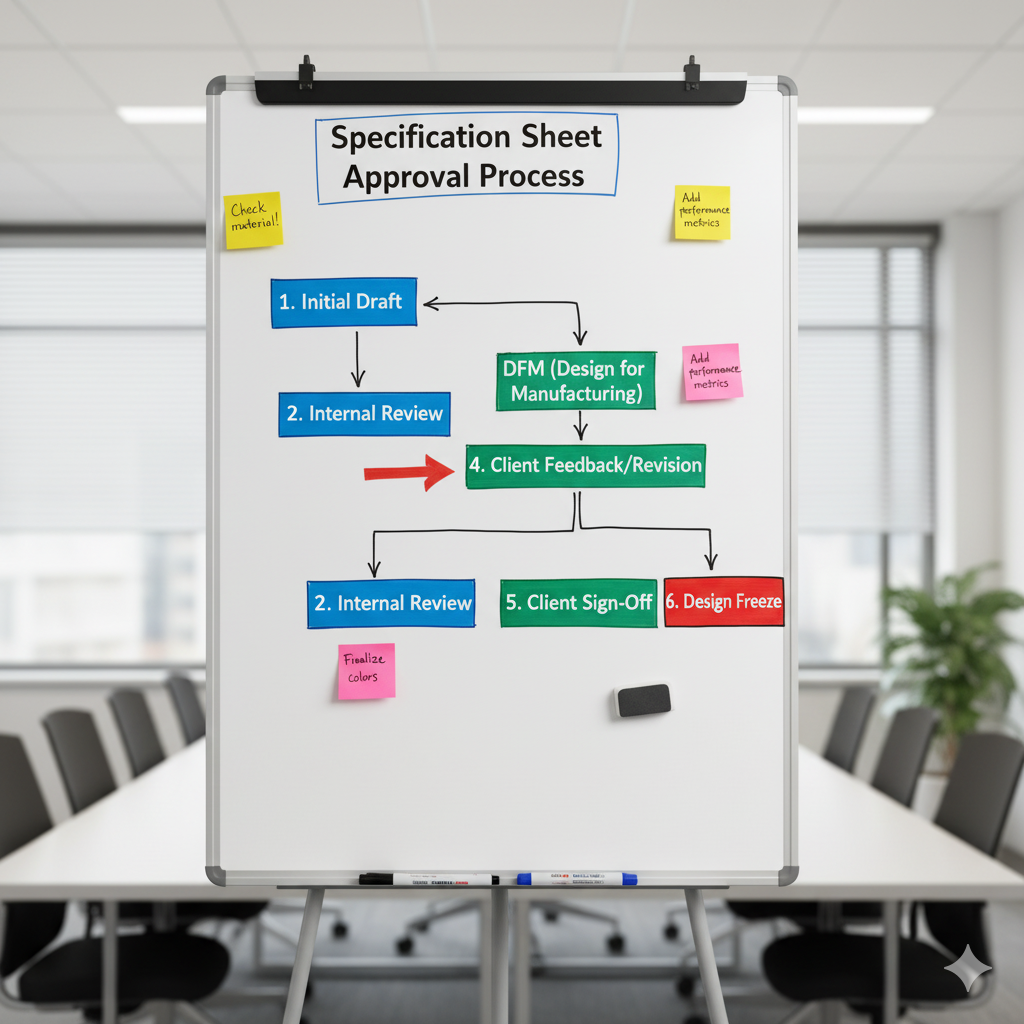

It becomes the standard through a formal, collaborative approval process that concludes with a "design freeze" and your official sign-off. It is, in effect, the final, legally binding addendum to our manufacturing agreement. A high-end retail brand used their approved spec sheet to correctly reject a batch from a previous supplier that used a slightly different plastic finish. The document gave them the objective evidence they needed to enforce their quality standards without argument.

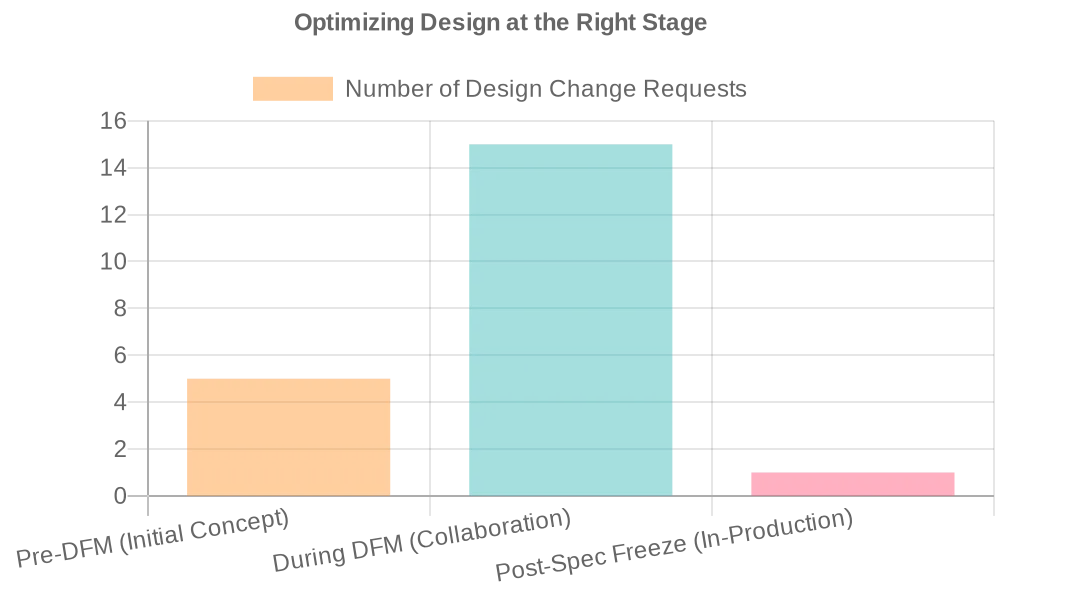

The specification sheet is a living document during development. It evolves through our collaborative DFM and prototyping process. But there is a critical moment when it becomes "frozen." This is a formal event. Once all prototypes are approved and all parameters are agreed upon, we send you the final version for your official review and signature. This signed document becomes the "Golden Standard." From that point forward, any deviation from this standard by our production team is considered a non-conformance.

Managing Revisions with Engineering Change Control

What if a change is needed after the standard has been frozen? We manage this with a rigorous and transparent Engineering Change Notice (ECN) process. A change is requested, we analyze its impact on cost and timeline, and we issue a formal ECN document. The change is only implemented after you have reviewed the ECN and provided your formal, written approval. This disciplined process ensures that the standard evolves only with your full knowledge and consent.

How Does the Spec Sheet Protect You from Unauthorized Changes?

Your biggest long-term risk is "quality fade"—the silent degradation of a product over time as a supplier secretly swaps components to cut costs. How does the spec sheet act as your shield against this? It's the cornerstone of true supplier quality assurance.

The signed specification sheet is your ultimate defense against "component fade." It is linked directly to your product's Bill of Materials (BOM), which lists the specific part number and manufacturer for every critical component. If a component supplier issues an "end-of-life" notice for a part, we cannot simply make a swap. This event automatically triggers our ECN protocol. We are contractually obligated to inform you, provide a proposed solution, and get your written approval. This is a core part of professional BOM management.

This system is built on a philosophy of proactive transparency. We don't wait for you to discover a change; we bring the change to you for a collaborative decision, ensuring the product you receive in year three is built to the exact same standard as the product you receive today.

The Product Specification Sheet is the most important document in your manufacturing journey. It is the definitive blueprint, the final quality standard, and the binding contract that governs our production. It transforms ambiguity into certainty and provides the foundation for a transparent, accountable, and ultimately low-risk manufacturing partnership. A detailed specification sheet is essential for any successful OEM product development and ensures your long-term success. We invite you to begin the process with us, to collaboratively craft the "constitution" that will guarantee your product's quality.