China Massager Electric Manufacturer: Can They Guarantee a 35-Day Lead Time?

- By Grace

- Updated on

Let's be honest. A delayed shipment or a last-minute quality problem isn't just an inconvenience; it's a direct hit to your bottom line. When you're sourcing massager electric products, these disruptions can wipe out your profits and tarnish the brand you've worked so hard to build. It’s not just about logistics. It’s about cutting through the "fog" of uncertainty that plagues too many sourcing partnerships with a portable massager manufacturer.

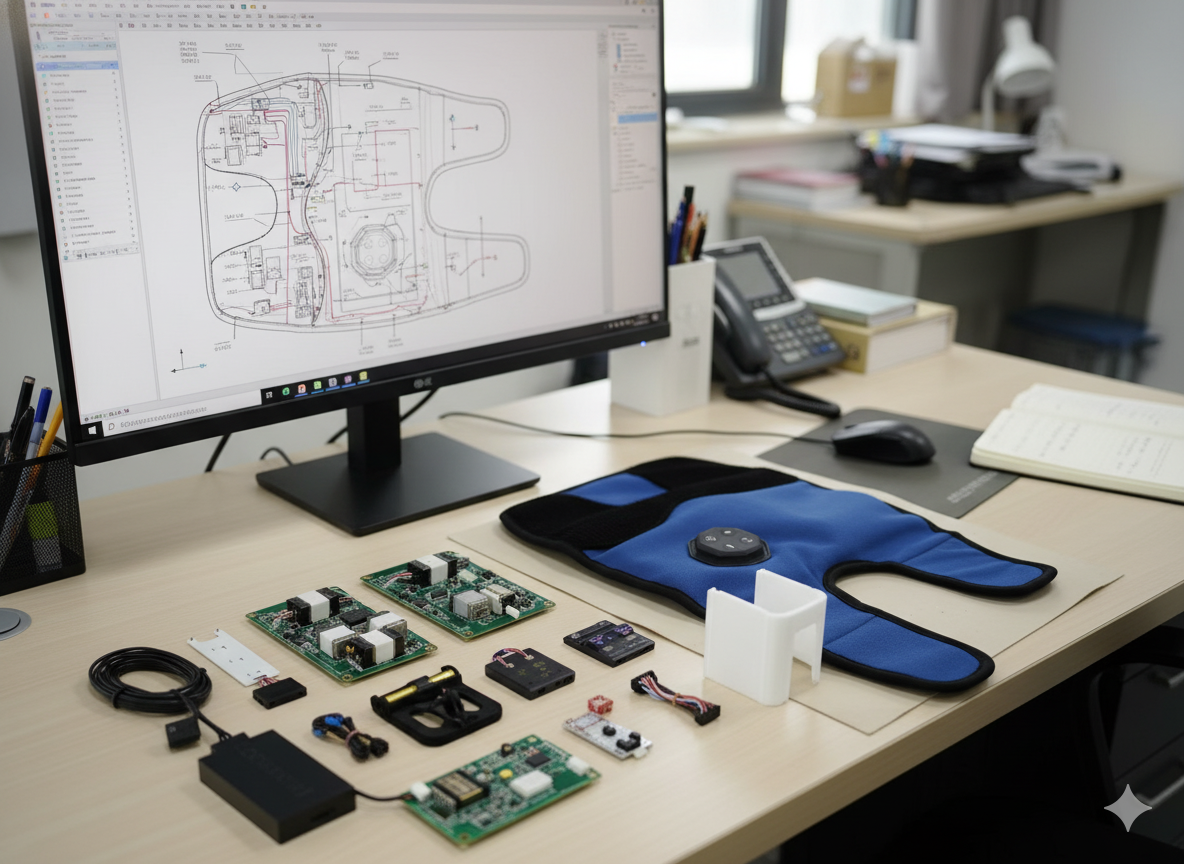

Here at KLCOSY, we’ve swapped that uncertainty for a system. We don’t just give you a lead time; as your dedicated OEM massager electric supplier, we give you predictability. We've built a transparent, process-driven framework that locks in reliability from the moment you sign the PO. This post will pull back the curtain on how our system works, turning your supply chain from a risk into a real competitive advantage.

We’ll walk through our standard timelines, what can affect them, and how we keep you in the loop so you’re always in control of your wholesale massage device from China.

So, What Does a "Standard" 30-45 Day Lead Time Really Mean?

Ever worry that a quoted lead time is just a best-guess that won't hold up under pressure? That feeling of uncertainty can make inventory planning a nightmare, forcing you to gamble on stocking levels for your massage machines right before a critical sales season.

We've built our entire production system on a simple idea: predictability is profit. I remember talking to the head of procurement for a major Canadian retailer. He told me our consistent delivery, planned months out, let them launch a holiday promotion that smashed sales targets by 30%. Why? Because they weren't hoping for their stock to arrive on time; they knew it would. Our dates weren't estimates; they were commitments from a China Massager Electric Manufacturer they could trust.

That 30 to 45-day lead time you see isn't just a number we pull out of thin air. It's the final output of a finely tuned, multi-stage process with built-in checks and balances. For a client like you, who values process over promises, seeing this structure is how trust is built. It’s all designed to be transparent and auditable, so there are no surprises when you're developing a private label body massager. Every stage is managed with obsessive detail, turning complex manufacturing into a predictable sequence of events. This is the bedrock of our Proactive Quality Assurance (PQA) promise—speed never comes at the expense of quality.

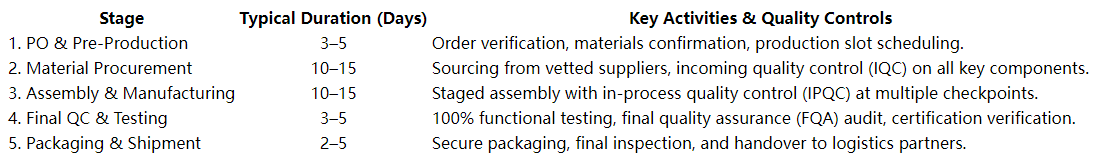

Deconstructing the Production Timeline

To give you total transparency, here’s a look at the core components of our production schedule. Think of it less as a simple sequence and more as a managed process, where every phase has its own quality gates and deadlines. This is how we spot potential issues long before they become delays.

Bottom line: this structured timeline is our commitment to you. By defining clear controls for each stage, we turn production from a reactive scramble into a proactive, manageable system.

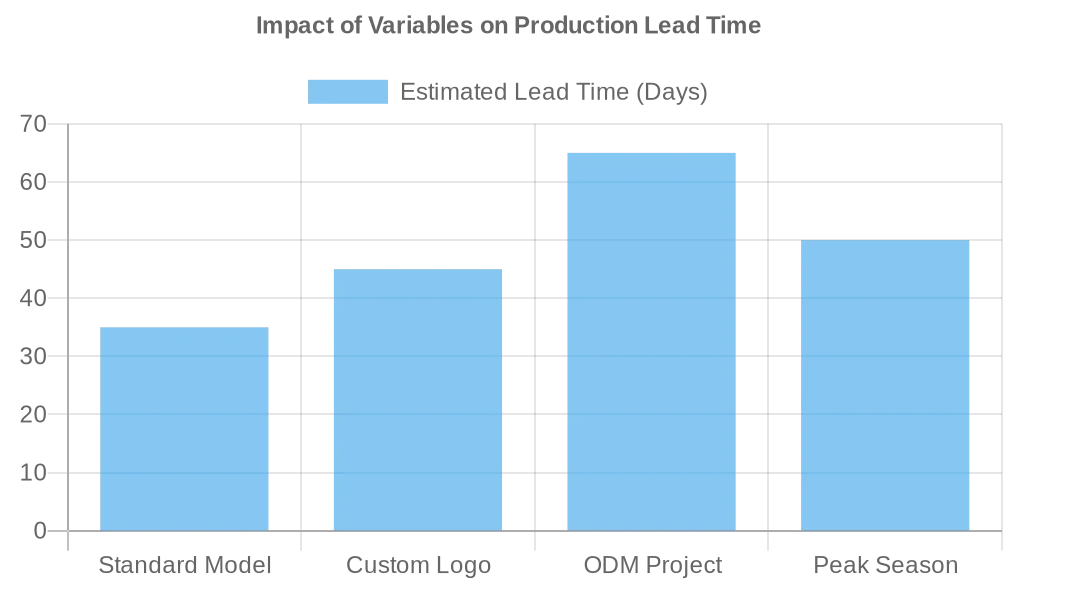

What Kinds of Things Can Affect Your Production Timeline?

You’ve probably been there: a supplier agrees to a complex customization, only to follow up with a string of unexpected delays and excuses. Those shifts don't just push back a delivery; they can derail an entire product launch and undermine your market strategy.

The difference between a successful custom project and a failed one usually comes down to process discipline. A brand owner we work with, who was launching a new line of medical-grade massagers, told us our detailed change control process was the clincher. Our Engineering Change Notice (ECN) system gave them the documentation and impact analysis they needed to confidently promise their distributors a firm launch date for their ODM massage machine. A date we hit, right on the dot.

While our 30-45 day lead time is the benchmark for our existing models, some variables will extend that timeline. The key isn’t to pretend they don’t exist, but to manage them with a transparent system. Our Proactive Quality Assurance (PQA) system is designed to anticipate these factors and give you a realistic schedule from day one. Whether it’s a simple logo change or a full-blown ODM project, we use a structured process to calculate the impact on the timeline so your forecast is always accurate. It’s how we protect your project goals.

Customization and Complexity

The biggest factor influencing lead time is the degree of customization. We classify changes into three tiers:

- Tier 1 (Aesthetic): Simple changes like custom colors, logos, or packaging tweaks. These typically add 7-10 days for sourcing and sample approval.

- Tier 2 (Component): Adjusting internal parts, like a specific motor or battery. This can add 10-15 days, depending on component availability and extra testing.

- Tier 3 (Structural/ODM): Creating a new mold or making significant changes to the product's design. This is the most intensive and requires a lead time of 60+ days to cover tooling, prototyping, and rigorous testing.

Order Volume and Seasonality

Larger orders can extend production, and so can seasonal peaks (especially the rush before Q4 and Chinese New Year). We get ahead of this by working with our clients to place orders in advance, securing production slots and pre-ordering critical components.

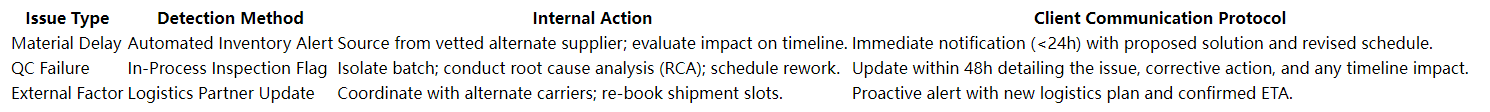

How We Handle Delays Proactively and Keep You in the Loop

Tired of chasing suppliers for updates, only to hear about a delay after it’s already messed up your schedule? That’s not a partnership; it’s a sign of a broken process. To show you how we do things differently, here's the exact communication protocol we follow. No fluff, just the system.

True partnerships are built on proactive communication. I’ll never forget what the quality manager for a leading spa chain told us after he switched to our company. He said, "For the first time, I don't have to ask what's going on. Your team tells me before I even think to ask. That's how I know you respect my business." Getting weekly production updates, complete with photos from the assembly line, gave him the confidence he needed.

Our philosophy here is simple: bad news doesn't get better with time. We've built a system that flags potential issues early, so we can fix them and give you a revised—but still reliable—schedule before a small hiccup becomes a major headache. This transparency is fundamental to our role as a manufacturing partner. Giving you full visibility, even when things are challenging, is the only way to build a supply chain you can count on. Our goal is to make our factory feel like an extension of your own operations.

In an industry where delays and "quality fade" feel like the norm, our process-driven approach is different. We provide the predictability, transparency, and reliability you need to build a truly resilient supply chain.

The ultimate proof of a supplier’s confidence is their willingness to be audited. So, I invite you to put our systems to the test. Request our Quality Manual, review our process documentation, or let’s schedule a virtual factory tour. We'd be happy to show you our commitment to quality in action.