ODM Portable Massagers: Can China Suppliers Handle R&D?

- By Grace

- Updated on

You have an innovative idea for a portable massager but lack the in-house engineering team to bring it to life. The process seems complex and risky. But what if you could find a single partner to handle everything?

From my experience as the head of KLCOSY, I can tell you: Yes, a good Chinese ODM (Original Design Manufacturer) for portable massagers can absolutely offer comprehensive R&D and engineering support. We function as a full-service extension of your team, providing everything from industrial design and mechanical engineering to firmware development and certification assistance.

Finding a factory is easy, but finding a true development partner is the key to success. This partner doesn't just build what you ask; they help you build it better. So, let's explore what this comprehensive support looks like and how you can identify a supplier with the right capabilities for your project.

How do I evaluate the R&D capabilities of a potential Chinese ODM partner for my custom massager?

Many factories claim to have strong R&D, but their websites all look the same. Choosing the wrong partner can lead to endless delays and a product that fails in the market. I'll show you how to see past the promises.

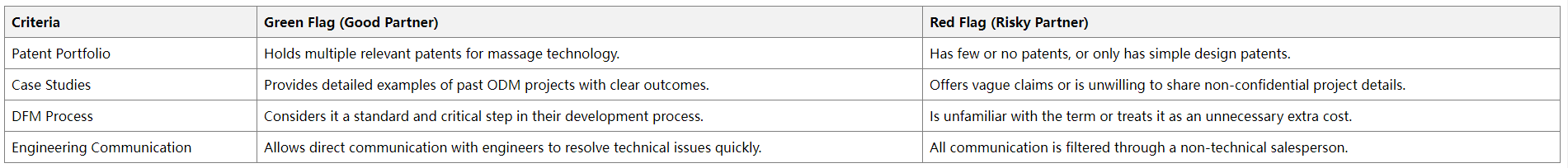

I always advise my clients to look beyond the number of employees or the factory's size. I've seen small, focused teams outperform large, bureaucratic ones. The real measures of a strong R&D department are its patent portfolio, the quality of its prototypes, and its understanding of Design for Manufacturability (DFM).

Evaluating a potential ODM's R&D strength requires you to look for specific evidence, not just accept their marketing claims. It's about asking the right questions and knowing what a good answer looks like. A supplier with a truly competent engineering team will be able to provide clear, detailed responses that demonstrate their expertise. They are not just assemblers; they are problem-solvers. This is the core difference between a basic factory and a strategic partner who can help you reduce risk and build a better product. Let's break down the key areas you should investigate to make an informed decision.

Look Beyond Team Size

A common mistake is to be impressed by a factory that boasts of having "50 R&D engineers." In my experience, the effectiveness of an R&D team is not about its size, but about its structure and expertise. A small, highly-skilled team with specialists in mechanical engineering, electronics, and firmware can be far more innovative and efficient than a large, disorganized department. Ask about the team's structure. Do they have dedicated project managers? Can you speak directly with an engineer, or is all communication filtered through a salesperson? Direct access to technical staff is a sign of a confident and capable team.

Scrutinize Their Portfolio and Patents

A supplier’s past work is the best predictor of their future performance. Ask to see a portfolio of ODM projects they have completed. Pay attention to the complexity and uniqueness of the designs. Are they just making slight variations of the same product, or do they have experience developing genuinely new devices? Furthermore, inquire about their patent portfolio. A factory that invests in its own patents demonstrates a commitment to innovation and an understanding of intellectual property. This shows they are creating original work, not just copying others, which reduces your risk of IP infringement issues down the line.

Request a DFM (Design for Manufacturability) Analysis

This is a critical test. A DFM analysis is a report where the engineering team reviews a product design and identifies potential issues that could make it difficult or expensive to manufacture consistently. A top-tier ODM will do this automatically. A weak supplier might not even know what it is. You can provide them with a basic concept or 3D model and ask for their DFM feedback. Their response will reveal their depth of knowledge. Do they suggest changes to improve assembly efficiency, reduce material waste, or increase the product's durability? This process shows they are thinking like a partner, focused on making your product successful and cost-effective in mass production.

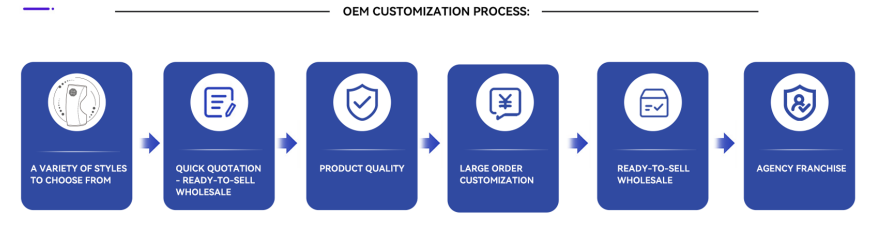

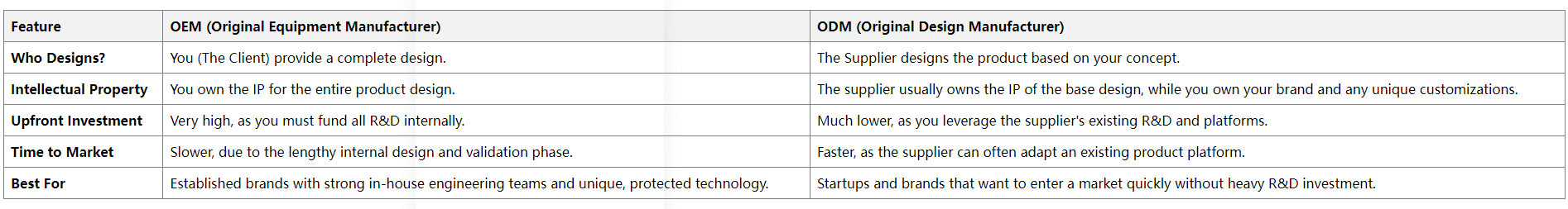

What's the difference between OEM and ODM services for portable massagers in China?

When searching for private label portable massagers in China, you'll constantly encounter the terms OEM and ODM. While both result in a product with your brand on it, they represent fundamentally different partnership models. Choosing the wrong one can waste time and money, or limit your product's potential. Let’s make the distinction crystal clear.

I often explain it to my clients like this: With OEM, you bring my team a finished blueprint, and we act as your hands to build the product. With ODM, you bring us an idea or a problem, and my R&D team creates the blueprint for you. ODM is a true partnership in innovation, making it ideal for brands that need a Chinese supplier to manage product development from the start.

Understanding the fundamental difference between OEM and ODM portable massagers is crucial. Your choice impacts everything from your upfront investment and development timeline to your level of control over the final product and its intellectual property. One model is about executing a pre-existing vision, while the other is about co-creating a new one. Let's dive deeper into the specifics of each model so you can confidently determine which one aligns with your goals.

Original Equipment Manufacturer (OEM): The "Build-to-Print" Model

In an OEM arrangement, you, the client, are responsible for the vast majority of the research and development. You provide the factory with a complete set of technical specifications. This includes detailed 3D CAD files for all parts, a full Bill of Materials (BOM) specifying every component, and often even the firmware that will run the device. The factory’s role is primarily execution: sourcing the specified components, manufacturing the parts, assembling the product, and performing quality control according to your standards. This model is ideal for companies that have a strong, experienced in-house design and engineering team. You maintain full control over your intellectual property and the product's design. However, it requires a significant upfront investment in R&D before you even approach a factory.

Original Design Manufacturer (ODM): The "Concept-to-Product" Model

The ODM model is a more collaborative partnership. You come to the supplier with a market need, a concept, or a list of desired features. For example, you might say, "I want a portable neck massager that uses heat, has three distinct massage modes, and a battery life of at least four hours." The ODM supplier's in-house R&D team then takes over. They handle the industrial design, mechanical and electrical engineering, firmware development, and prototyping. They leverage their existing experience, technology platforms, and supply chain relationships to develop a product that meets your requirements. This approach dramatically lowers your R&D burden and allows for a much faster time to market. It's perfect for brands that excel at marketing and sales but don't have a large engineering department.

Can a Chinese supplier manage the entire product development process for my unique massager design?

You want a single, reliable partner to take your project from a simple sketch all the way to a packaged product. Juggling different design firms, engineering consultants, and factories is a recipe for disaster. The good news is, you don't have to.

Absolutely. In my role at KLCOSY, I've personally managed projects that began as a drawing on a napkin and are now selling on retail shelves in Canada and Australia. A true ODM partner is built to handle the entire lifecycle, so you can focus on building your brand and selling the product.

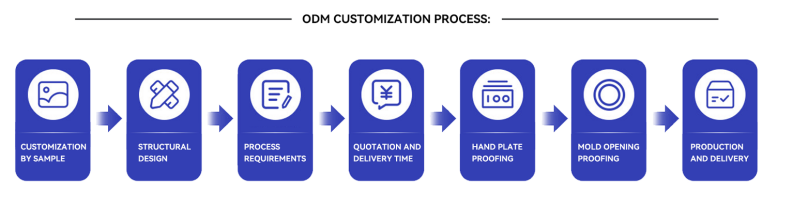

A comprehensive ODM service provider acts as your project manager, engineer, supply chain expert, and quality controller, all rolled into one. This integrated approach is designed to be a seamless, "one-stop" solution. It eliminates the communication gaps and finger-pointing that can happen when multiple independent companies are involved. The process is typically broken down into clear stages, each with specific milestones and deliverables. From the initial brainstorming session to the final product being loaded onto a container ship, a capable ODM supplier will guide you through every step, ensuring a smooth transition from one phase to the next.

Stage 1: Concept, Design, and Engineering

This is where your idea begins to take physical form. It starts with industrial design, where designers create sketches and 3D renderings to define the product's aesthetics and ergonomics. Once a look is approved, mechanical engineers take over. They design the internal structure, ensuring all components like the motor, battery, and circuit board fit perfectly and can withstand use. At the same time, electrical engineers design the Printed Circuit Board (PCB) that acts as the product's brain. Throughout this stage, there is a strong focus on material science, selecting the right plastics, silicone, and metals for durability, feel, and cost.

Stage 2: Prototyping and Validation

Once the digital design is complete, it's time to create physical prototypes. Early prototypes are often 3D printed to quickly check for fit and form. Later, fully functional prototypes are made using processes that closely mimic mass production. These samples are not just for you to approve; they undergo rigorous internal testing. This includes performance tests (Does the motor deliver enough power?), safety tests (Does it overheat?), and durability tests (Can it survive being dropped?). This iterative process of building, testing, and refining is crucial for working out any flaws before committing to expensive production tooling.

Stage 3: Tooling, Sourcing, and Manufacturing

After the final prototype is approved, the project moves into the manufacturing phase. The first step is creating the injection molds, which are the steel tools used to produce the plastic parts in high volume. This is a significant investment, so getting the design right in the previous stage is critical. While the tools are being made, the supplier’s sourcing team manages the supply chain, ordering all the necessary components from their network of trusted vendors. Once all parts and tools are ready, a pilot production run is conducted to set up the assembly line and finalize the quality control procedures before full mass production begins.

Does a strong R&D team at a Chinese factory reduce my risk of product quality issues?

You’re worried about product quality. One bad batch of massagers could destroy your brand's reputation and lead to a mountain of costly returns. It's a valid concern for anyone manufacturing overseas. But the solution starts long before the assembly line.

A strong R&D team is the single most important factor in preventing quality issues. I tell my clients that my engineers don't just design a product; they design *how to build it well*. They identify and solve potential manufacturing problems on the computer, which is infinitely cheaper and better than discovering them on the factory floor.

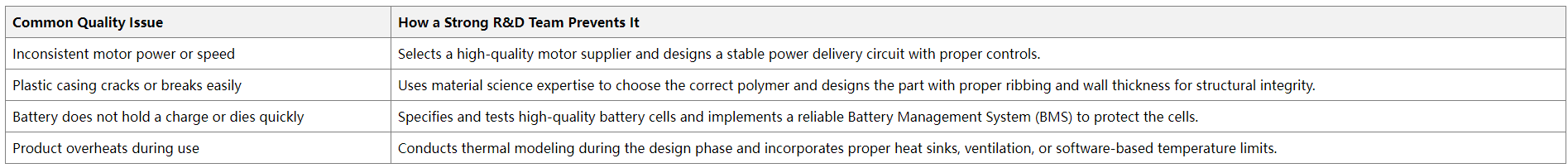

The connection between R&D and final product quality is direct and powerful. Many buyers think quality is simply about having inspectors on the assembly line. While that is important, it's a reactive approach—it catches defects after they've already been made. A truly quality-focused approach is proactive. It starts in the design phase. A skilled R&D team builds quality, reliability, and manufacturability into the product from the very beginning. They are your first and most effective line of defense against the kinds of systemic problems that lead to product failures and customer dissatisfaction.

Proactive Problem-Solving with DFM

As mentioned earlier, Design for Manufacturability (DFM) is a core practice of any elite R&D team. They obsess over details that might seem small but have a huge impact on quality. For example, they will design parts that can only be assembled in the correct orientation, making it impossible for a worker to make a mistake. They simplify the internal layout to reduce the number of steps and wires, which reduces potential points of failure. This proactive mindset means they solve problems before they can even happen, leading to a more consistent and reliable product.

Intelligent Component Selection and Sourcing

The performance of an electric massager depends on its weakest component. Poor-quality electric motors produce noise and are prone to premature damage. Low-quality batteries may pose fire hazards. Single-layer airbags can lead to air leakage. Cheap heating elements are likely to break easily. A strong R&D team has in-depth knowledge of the component supply chain. They test and verify components from different suppliers. They do not simply choose the cheapest electronic parts; they select batteries from suppliers known for the consistency and safety of electronic parts. They choose motors, air pumps, and heating elements that not only meet power requirements but also have a long-term reliability record. This expertise in component selection is a key part of ensuring product quality and is often not easily noticeable..

Creating Robust Testing Protocols

The R&D team doesn't just design the product; they also design the tests to validate it. Because they know the design inside and out, they know its potential weak points. They create the specific Quality Control (QC) plan that will be used on the assembly line. They develop custom testing jigs and equipment to check every unit for things like power output, battery performance, and button functionality. They define the standards for accelerated life testing, where products are run continuously for hundreds of hours to simulate years of use. This ensures that quality isn't just a matter of opinion but is measured against clear, objective engineering standards.

Conclusion

A capable Chinese ODM partner is far more than just a manufacturer. They are a full-service R&D and engineering extension of your team, essential for bringing a successful product to market. Whether you need a full-service partner for ODM portable massagers or a precise manufacturer for an OEM project, the key is to evaluate a Chinese portable massager supplier based on their engineering depth, not just their factory size. By choosing a partner with a strong R&D foundation, you can effectively manage the entire product development lifecycle and significantly reduce your risk of quality issues, ensuring your final product is a success.