Massager Casing Materials: A B2B Sourcing Guide (ABS, PC, Silicone)

- By Grace

- Updated on

I've seen so many promising products fail for one simple reason: they just felt cheap in the hand. As a procurement manager, you're staring at a spec sheet, comparing quotes with codes like ABS, PC, or Silicone. It's easy to see these as just line items driving your unit cost. But your customers don't see a spec sheet. They hold the product. And that first touch is a promise of quality—a promise made entirely by the massager casing materials.

I'm Tony, CEO of KLCOSY, and we believe choosing a material isn't a cost decision; it's a brand decision. The right choice in your massager product design can justify a premium price point and earn five-star reviews, while the wrong one can lead to a flood of returns that permanently damages your reputation. It’s the difference between a product customers love and one they just tolerate.

Let's cut through the technical jargon. I'll give you the straightforward framework we use to guide our partners, helping you select the perfect material that balances cost, durability, and the premium feel your brand deserves.

So, Is ABS Plastic "Good Enough" for Your Brand?

This is the classic dilemma. You're trying to hit a competitive price point, but you're worried the final product will feel brittle or look like a toy. It's a valid fear, and getting it wrong is a surefire way to get stuck with inventory that just won't move.

An online retail partner told us that for a major holiday promotion, they needed a high-volume, cost-effective hand massager. We guided them to a high-grade ABS with a matte finish. The result? They hit their target cost, and their return rate was under 2%—a massive success for that category.

Think of ABS (Acrylonitrile Butadiene Styrene) as the reliable workhorse of the plastics world. It’s cost-effective, lightweight, and incredibly versatile, making the ABS plastic massager the standard choice for most consumer electronics. Its main advantage is that it flows beautifully into injection molds, allowing us to create complex, ergonomic shapes without driving up tooling costs. But the key isn't just choosing ABS; it's elevating it. By using high-grade steel molds and offering a range of premium finishes—from a modern, fingerprint-resistant matte to a sleek high-gloss—we can make an ABS product feel substantial and look fantastic.

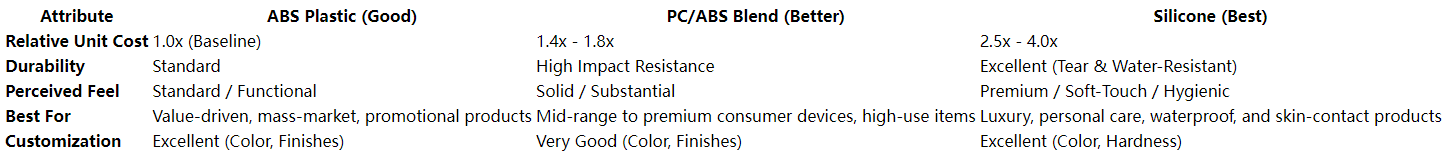

A Quick Head-to-Head Comparison

To make an informed decision, you need a clear snapshot. Here’s a simple breakdown of the most common private label massager materials.

When Should You Upgrade to PC or Blends?

Okay, let's say your product is meant to take a beating. Maybe it's for a gym, a physical therapy clinic, or a corporate wellness room. You're worried a standard plastic casing will crack if dropped or show scuffs too quickly, damaging your brand's reputation for quality.

I remember a corporate wellness manager telling us the massagers in their high-traffic relaxation rooms were constantly breaking. After they switched to our model with a PC/ABS blend casing, they saw a 90% reduction in device failures over the first year. It was a clear win for their budget and their employees' morale.

This is exactly where Polycarbonate (PC) and its blends shine. A polycarbonate massager offers a serious upgrade in toughness. This is the same family of polymers used to make motorcycle helmets and bullet-resistant glass. It offers significantly higher impact resistance than standard ABS, meaning it can withstand daily abuse without cracking. When we blend it with ABS, we get the best of both worlds: the strength of PC with the excellent moldability of ABS. For an even bigger boost, we can reinforce the polymer with glass fibers (GF). Adding 10-20% GF is like adding rebar to concrete; it dramatically increases the casing’s rigidity, prevents creaking, and contributes to a much more solid, high-quality feel. This is a strategic investment in your massager material selection.

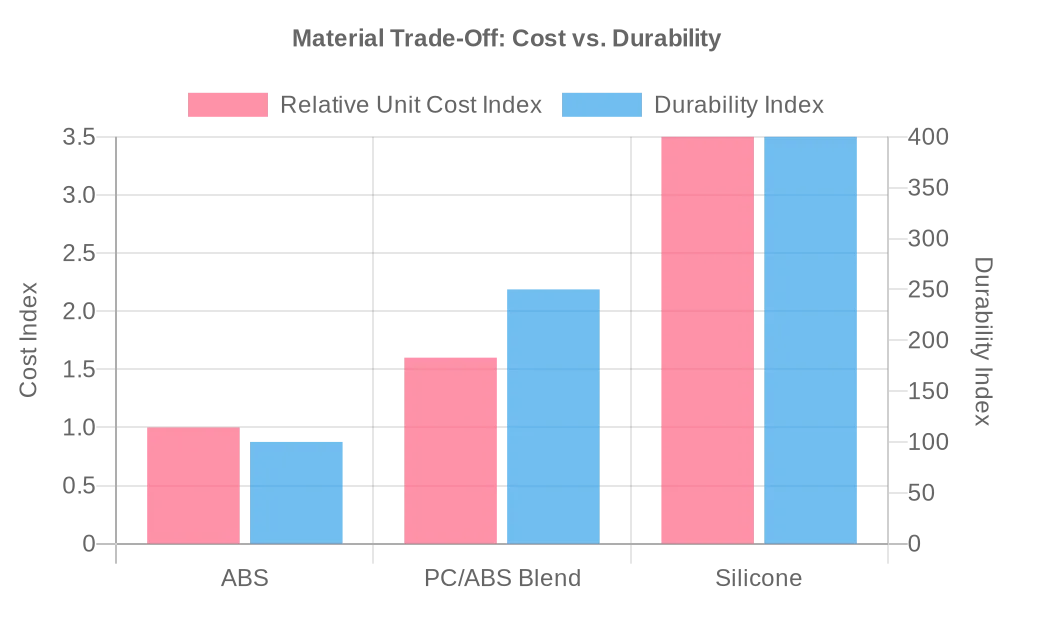

The Cost vs. Durability Payoff

The decision to upgrade is a clear cost-benefit analysis. As you can see below, the jump in durability often justifies the moderate increase in cost, answering the question of cost vs durability of massager materials.

Is Silicone Worth the Investment?

You're aiming for the top shelf. Your target customer prioritizes comfort, hygiene, and a luxurious feel. Your product needs to feel like an extension of their personal care routine—soft, safe, and impeccably clean.

One of our partners, a founder of a high-end wellness brand, put it perfectly. She said that launching with our body-safe silicone-encased massager was key to their brand identity. "The seamless, velvety feel of the silicone communicates comfort and quality before the customer even turns it on," she told me.

For a truly premium or "personal" product, a medical-grade silicone casing is the superior choice. This involves overmolding a seamless layer of liquid silicone rubber (LSR) over a rigid internal frame. This creates a fully-sealed, waterproof, and incredibly hygienic device. The tactile experience is unmatched; its soft, skin-safe feel immediately communicates comfort and luxury. Silicone is non-porous, making it easy to clean and resistant to bacteria buildup. While this advanced process comes at a higher unit cost, it's a strategic choice for a flagship model where the brand story is built around wellness, safety, and a premium sensory experience.

Don't Forget the Final Touches

Figuring out how to choose casing material for a massager also means thinking about ergonomics. Regardless of the main casing, we can integrate overmolded TPE or medical-grade silicone for soft, comfortable grip zones. But to remove all guesswork, we always provide physical samples. Before you commit, you will hold your product in your hands, finished in the exact materials you specified. This ensures the final product perfectly matches your vision.

The material you choose is the first thing your customer will notice. It's their first physical handshake with your brand. By using a tiered strategy—ABS for value, PC blends for performance, and silicone for premium—you can build a product line that meets the expectations of every customer. A clear understanding of massager casing materials is fundamental to smart product development.

Ready to feel the difference for yourself? Contact our team to request a physical sample kit of our material and finish options. Let's build a product that makes an unforgettable first impression.